ITAZ

SERVICES

ENGINEERING

CONSULTING

DEVELOPMENT

OF HYDRAULIC

COMPONENTS

AIR PUMPS

SCR TECHNOLOGY

COMPONENTS

DEVELOPMENT

ECO-FRIENDLY MOBILITY

WITH HYDROGEN

INJECTORS

MODERN

ENGINE

TECHNOLOGIES

VALIDATION

AND TEST

FMEA

DESIGN SOLUTION-

TECHNICAL

COATINGS

ANALYSYS

LABORATORY

PROTOTYPE

MANUFACTURING

More than 40 years’ experience

With more than 40 years’ experience, our customers from the automotive and industrial sectors have been convinced of our capabilities and results in developments and services.

Sustainbility

We develop sustainable technologies to protect the environment. Our goal is to support our customers in reducing CO2 emissions.

ENGINEERING

Brainstorming

Design

Simulation1D, FEM, CFD

Project management

Simultaneous Engineering

Engineering and service

iTaz carries out developments from the white sheet to series production launches or partial developments (production with partners or customers).

CONSULTING

Business development

Supplier support and development

Problem solving, methods and moderation

Six Sigma Application

Enhancements Implementations

Risk management

Consulting, analysis, solution finding

New approaches, improved processes, optimized processes and good decision-making basis – the benefit of our customers and compete successfully in the market. We provide competent advice on technology and management issues and use our expert knowledge and a structured approach to develop individual solutions.

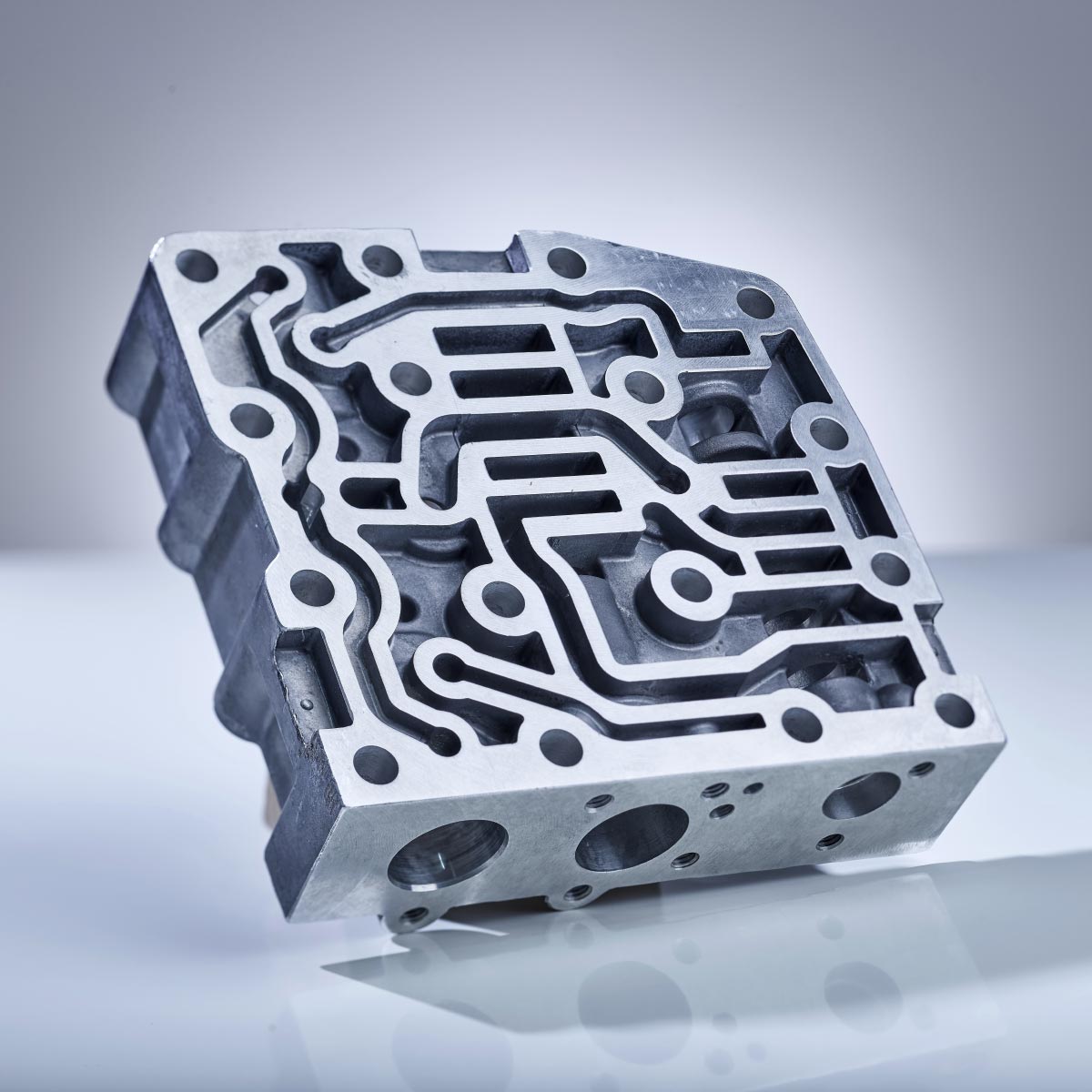

DEVELOPMENT OF HYDRAULIC COMPONENTS

Valves

Proportional, On/Off, Injektoren

Pumps

Oil, gasoline, diesel, gas, urea, water

Diesel

Injection systems, injectors, pumps, lines

Gasoline

Injection systems, injectors, pumps, lines

Mechanical devices

Variable Valve Train

Electromechanical locks

With more than 40 years of experience in hydraulics, we have already developed and implemented countless hydraulic projects. In this field we know exactly what to do, regardless of the technical application, the medium, pressure, flow rate, material selection, production process, etc. Hydraulics is where we are at home.

Some examples are:

- Valves

- Pumps

- System components

Valve technology / Injector technology

We develop valves and injectors for various applications. These include classic designs as proportional or switching valves for liquid media with flow or pressure-control functions.

Pressure Supplies

Our development services include the design, development, calculation such as simulation, creation of prototypes, functional measurements, validation of the pumps, as well as the support of series suppliers up to the SOP.

Application examples for pressure supplies

- Hydraulic pumps

- Hydraulic power packs

- Air pumps

Transmission technology

- The development focus of iTaz in transmission technology is on

- Pumps

- Valves

- Actuators

AIR PUMPS

Exhaust aftertreatment

Air supported SCR Systems

Air supply for catalyst heating

Pneumatic controls

Air pumps for controls

Air Supply

Different requirements are placed on pumps for the supply of exhaust gas aftertreatment or other systems.

We offer a wide range of pump solutions, whether piston or rotary and diaphragm pumps.

We are sure to have a version especially for you.

SCR TECHNOLOGY – COMPONENTS DEVELOPMENT

SCR-technology – Components development

iTaz develops key components for SCR systems

-

- Pumps – for urea and/or air support at urea injection.

- Injectors – with or without air support for car, truck or off-road applications.

Eco-friendly mobility with hydrogen injectors

Directly injection injectors for the hydrogen engine can be carried out in different sizes. In direct controlled and as pilot control for the needle.

environmental friendly mobility with hydrogen injectors

Hydrogen combustion engines are almost mission-free. Through the further development and use of this technology, we create the possibility of short-term high CO2 reductions in traffic. Since hydrogen combustion is highly compatible with existing internal combustion engines, it can be implemented in existing vehicle fleets in a resource-saving manner using existing production facilities.

MODERN ENGINE

TECHNOLOGIES

Together with partners, we develop modern engine concepts to increase efficiency.

Modern engine technologies

For decades we have been developing technologies that reduce consumption and emissions while increasing power and torque. These technologies can now also be used in modern, low-emission internal combustion engines.

If these engines are operated with a CO2-neutral synthetic fuel or natural gas or hydrogen, compression, injection time, valve lift and other influences also affect the combustion.

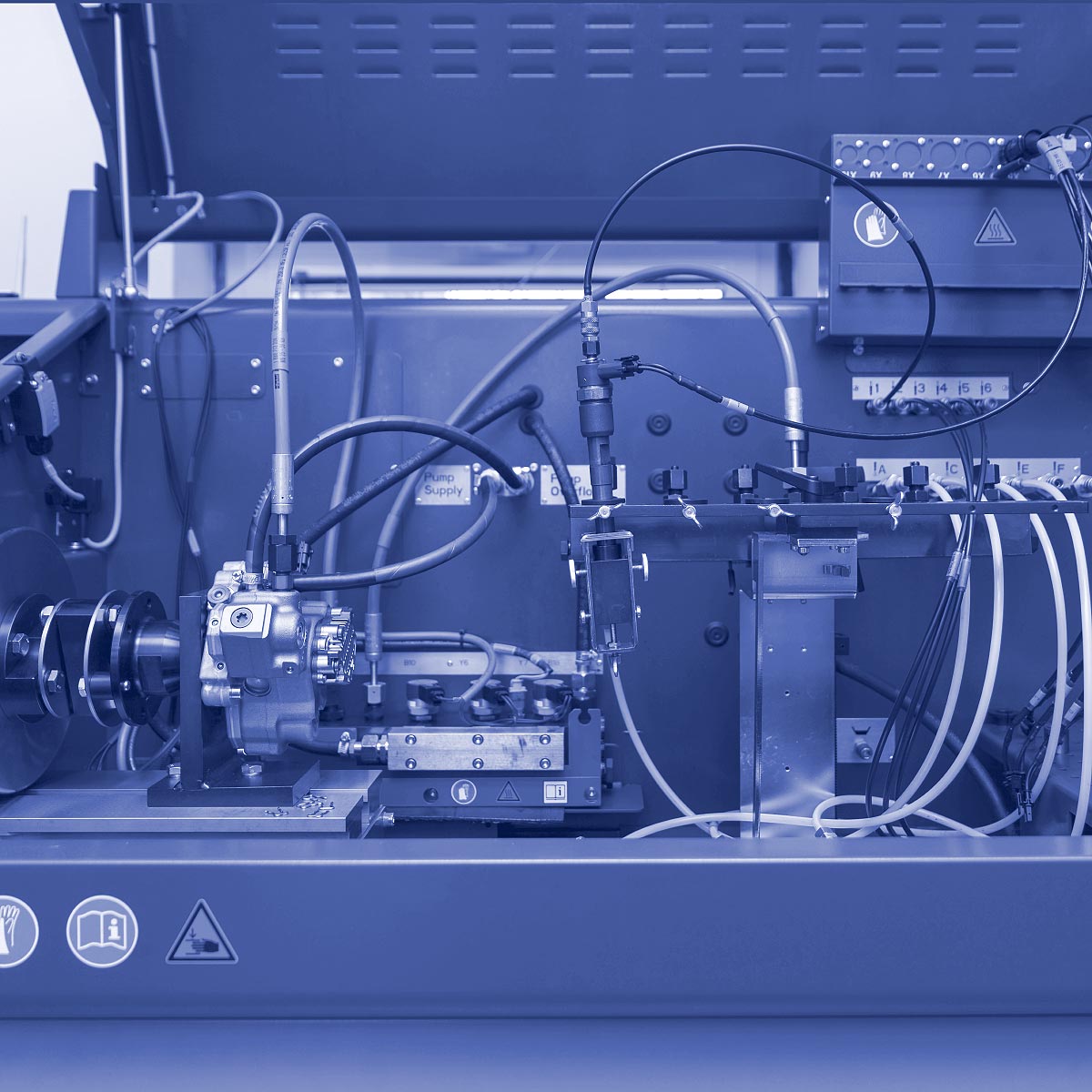

VALIDATION AND TEST

Validation is part of our development process and accompanies us through the different development steps of the A-B-C sample phases.

Validation and test

Validation is part of our development process and accompanies us through the various development steps of the A, B and C sample phases. We use function tests to verify our products right through to production launches. The component analysis determines the current component condition, and we use the lessons learned process to improve the product on the basis of the experience we have gained.

FMEA

Our service offers the FMEA as a service for our customers. We moderate design, process and system FMEA.

An effective method to recognize and avoid errors in the early project phases is the FMEA. This team-oriented analysis is used to find and evaluate sources of error in products and processes in advance.

DESIGN SOLUTION-TECHNICAL

Technical high-tech coatings are part of our design kit to achieve the necessary service life. Hard layers allow a lightweight design, e.g. with aluminum, with wear-resistant surfaces, even here is no way for the wear of time.

Design solution-Technical coatings

In order to achieve the required service life, technical coatings are used at critical points.

-

- DLC, WLC

- Nickel, Chrome

- Hybrid coatings

ANALYSIS – LABORATORY

As a service or in our development projects, analysis is a very important matter. The findings from the damage patterns provide positive results for the improvement of the product.

Analysis – laboratory

We use analyzes for components and materials for our own projects but also offer them as a service for our customers.

PROTOTYPE MANUFACTURING

Prototypes confirm our design!

Proving a function via the hardware is one of the most important steps in development. We attach great importance to our own production in order to verify devices and components.

Prototype manufacturing

Prototypes confirm our design! Proof of a function via hardware is one of the most important steps in development. We value our own production to verify devices and components. The further the sample phases progress, the more potential suppliers are involved in order to gain experience with the components. The fully developed product is mass-produced by our customers or partners.